The purpose of forging and causes of forging cracks

1. Forging cracks caused by defects in raw materials;

2. Forging cracks caused by improper forging process.

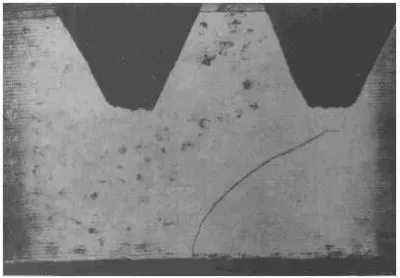

The macroscopic shape of the crack is firstly distinguished, and the transverse direction is generally independent of the base metal. The longitudinal crack needs to be combined and analyzed with the crack form and the forging process.

Decarburization on both sides of the crack is definitely caused during the forging process. Whether it is caused by the defects in raw material or the imprope forging process needs to be analyzed according to the metallographic phase and the technological process.

For the same batch of the same type of workpiece, the forging cracks are basically in one position, which is shallow under the microscope and decarburized on both sides. The material cracks do not necessarily repeat at the same position, and the depth under the microscope varies. More observations and more analysis, there are still certain regular patterns.

Most of the material cracks are consistent with the longitudinal direction of the material. There are two kinds of forging cracks, one is caused by overheating and over burning, and there is oxidative decarburization near the crack. And the other crack is caused by cold iron, which is a phenomenon in which the lattice breaks and tears. It can be distinguished from the metallography.

The purpose of forging:

1. Forming requirements;

2, improve the internal organization of the material, refine the grain, uniform element composition and organization;

3. Make the material more dense (the shrinkage or looseness of the original unexposed air inside the forged material, etc.), and the streamline distribution more reasonable;

4. Serve the next process through reasonable post-forging heat treatment.

Therefore, forging the certain defects in the raw materials is necessary. Large castings and forgings are often started directly from forging of steel ingots. There must be a large number of smelting defects inside the steel ingots. Obviously, reasonable forging can forge the so-called "defects". Therefore, the rationality of the forging process is the main reason for determining whether the forging will crack.

Of course, compared with a stable forging process, if the raw material defect level control requirement is given beforehand for the raw material before forging, we can recognize it as "forging crack caused by raw material defeat" when the raw material defect level exceeds the requirement and the cracking occurs in the original forging process.

The crack problem should be analysed according to the specific condition, combined with the analysis of the process, including whether the heating process has a protective atmosphere should be considered. The raw material cracks should be forged to be coherent. The oxide skin is usually dense and grey, and the dirt caused by the sample preparation process is very loose, and the color is black, which is known from the high-power microscope.