Installation and maintenance method of ball valves

1. It must be confirmed that the pipeline and trunnion mounted ball valve have been cleaned before operation.

2. The actuator operation of the valve drives the rotation of the valve stem according to the size of the input signal: when the forward rotation is 1/4 turn (900), the valve is closed. The valve opens when rotated 1/4 turn (900) in the opposite direction.

3. When the actuator direction indicator arrow is parallel to the pipeline, the valve opens; when the arrow is perpendicular to the pipeline, the ball valve closes.

Ball valve maintenance:

Longer service life and maintenance-free time will depend on several factors:

Maintain a harmonious temperature/pressure ratio under normal operating conditions, and reasonable corrosion data.

Note: The fluid pressure in the valve body still exists when the ball valve is closed.

Remove line pressure and open valve in position before servicing

Disconnect power or air supply before servicing

Disengage the actuator from the bracket before servicing

1. packing lock

If the stuffing box is in the micro-leakage filling, the stem nut must be locked.

Note: Do not lock it, usually lock 1 / 4 ring to 1 ring, the leak will stop.

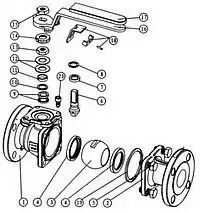

2. replace the valve seat and seals

A. disassembly

With the ball valve in the half-open position, flush hazardous materials that may be present inside and outside the valve.

Close the ball valve, remove the bolts and nuts on the flanges on both sides, and completely remove the valve from the pipe.

Disassemble the drive unit-actuator, connecting yoke, lock washer, stem nut, wear plate and stem packing.

Remove the body cover connecting bolts and nuts, separate the bonnet from the valve body, and remove the bonnet gasket.

Verify that the ball is in the "off" position, which allows it to be easily removed from the valve body and then the seat removed.

Push the valve stem down from the hole in the valve body until it is completely removed, then remove the O-ring and packing ring.

Note: Exercise caution to avoid scratching the stem surface and the packing seal of the valve.

B. reassembly

It is highly recommended to replace the seat and bonnet gaskets and seals with spare parts packages to clean and inspect the parts of the parts being inspected.

The assembly is reversed in the order of disassembly.

Use the specified torque to cross-tighten the flange bolts.

Lock the nut with the specified torque.

After the actuator is installed, the valve stem is rotated to rotate the corresponding input signal to open and close the valve.

If possible, perform the pressure test and performance test of the valve according to the standard after installing the pipe.