Knowledge of Forged Steel Valve Electric Actuators-part one

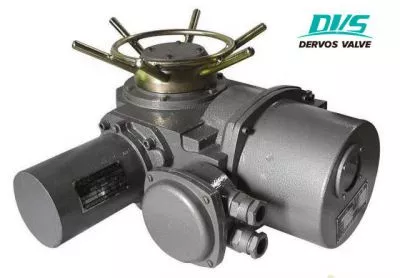

1. Forged steel valve electric actuators generally consist of the following parts:

• Specific motor, characterized by strong overload capability, large starting torque, small rotational inertia, short working time, intermittent operation

• Speed reduction mechanism to reduce the output speed of the motor

• Stroke control mechanism to adjust and accurately control the opening and closing position of the forged steel valve

• Torque limiting mechanism to adjust the torque (or thrust) and make it not exceed a predetermined value

• Manual, electric switching mechanism, interlocking mechanism for manual or electric operation

• Opening indicator to indicate where the forged steel valve is in the process of opening and closing

2. Select electric actuator according to the type of forged steel valve

Angular stroke electric actuator

Angle-stroke electric actuator (angle < 360 degrees) is suitable for forged steel butterfly valves, forged steel ball valves, forged steel plug valves, etc.

The rotation of the output shaft of the electric actuator is less than one circumference, that is, less than 360 degrees, usually 90 degrees, to achieve the opening and closing process control of the forged steel valve. Such electric actuators are divided into direct connection type and base crank type according to different installation interface modes.

• Direct connection type: It refers to the form in which the output shaft of the electric actuator is directly connected to the valve stem.

• Base crank type: It refers to the form in which the output shaft of the electric actuator is connected to the valve stem through the crank.

Multi-turn electric actuator

Multi-turn electric actuator (angle > 360 degrees) is suitable for forged steel gate valves, forged steel globe valves, etc.

The rotation of the output shaft of the electric actuator is greater than one circumference, that is, greater than 360 degrees. Generally, multiple turns are required to control the opening and closing process of the forged steel valve.

Straight stroke

Straight stroke (linear motion) electric actuator is suitable for single seated forged steel regulating valves, two seated forged steel regulating valves, etc.

The movement of the output shaft of the electric actuator is linear, not in the form of rotation.